Haynes Owner’s Workshop Manuals: a series of handbooks designed to guide people in the maintenance and repair of their automotive vehicles. Having sold more than 200 million copies, Haynes have established themselves as one of the leading providers of automotive literature.

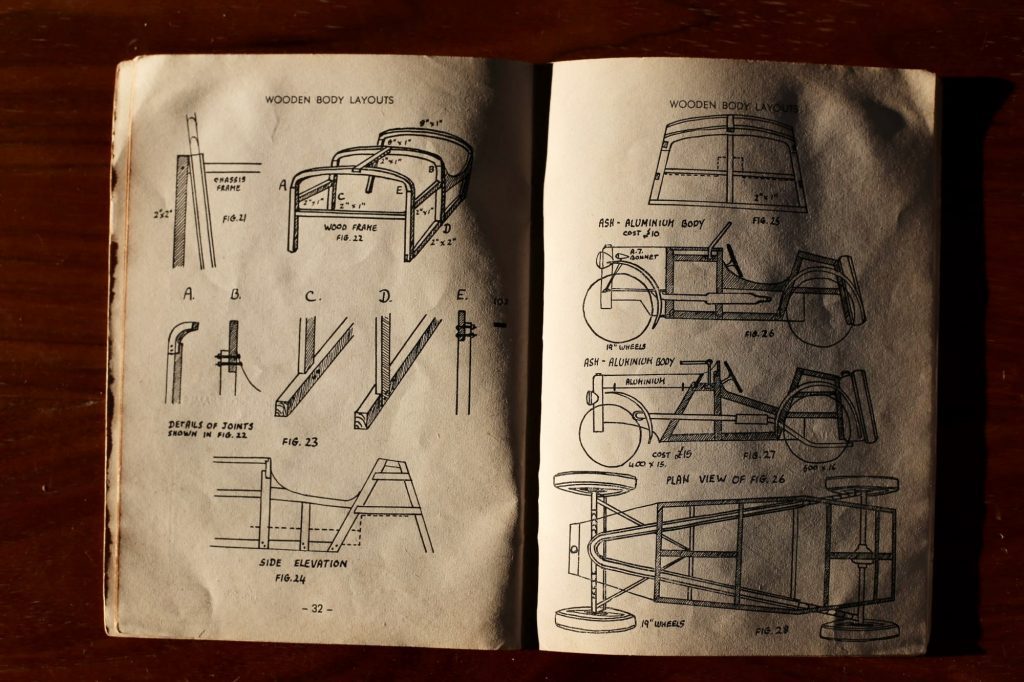

The history of Haynes Manuals begins four years prior to the founding of JH Haynes & Co in 1960. At the age of 16, John Haynes wrote his first book detailing modifications for the Austin 7 (750 Special), which he then sold, giving him the idea to produce and sell more manuals. The first official Haynes manual was published in 1965 and since then, the company has completed over 2,000 teardowns, resulting in the creation of more than 600 manuals.

When Haynes was founded, workshop manuals were already on the market. However, the cars had not before been stripped down and the manuals did not include step-by-step photographs of the process. Two features that later became established standards for many instructions and manuals. With a history spanning over 60 years, Haynes have not only helped people fix their cars but have also become synonymous with knowledge and self-accomplishment. Their manuals have made people feel proud of a job they have personally done without having to rely on expensive tools or additional outside expertise.

Key Characteristics of Haynes Manuals

Essential: Haynes’ products are instruction manuals, so naturally, the company has strived to make them as great as possible. They fixed the issue of car manufacturers’ poor instructions by providing a better alternative with their manuals.

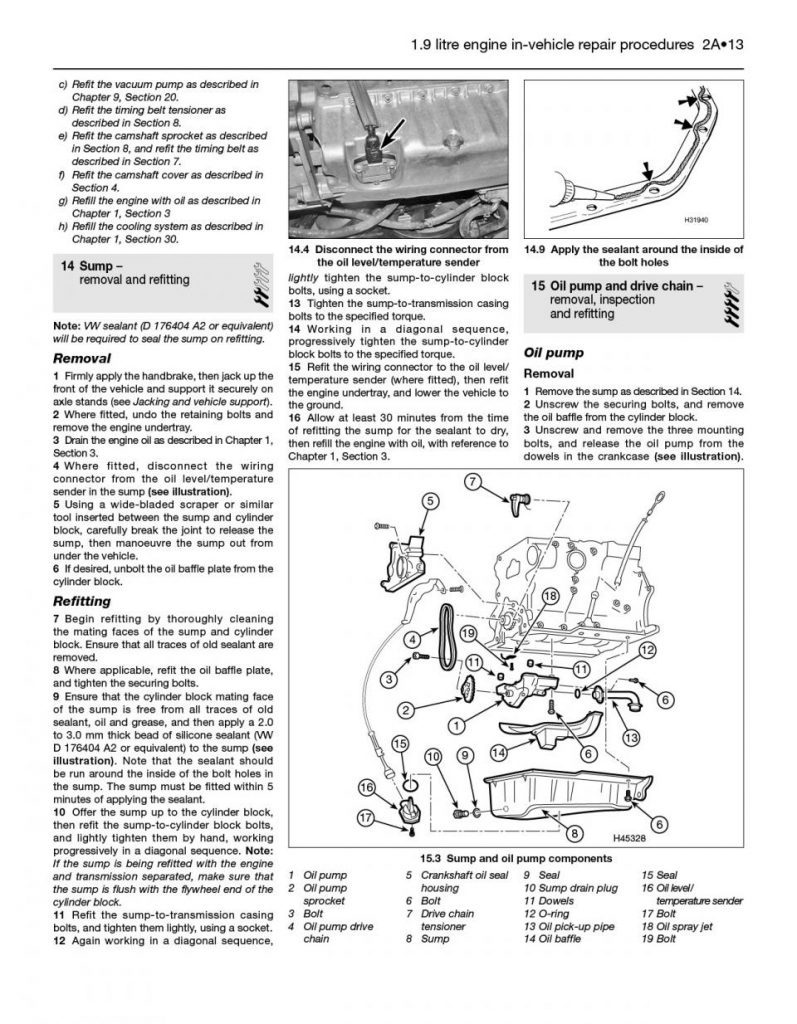

Dedication: The creation of each manual is based on a complete strip-down of the vehicle, a process that is carefully documented step-by-step. Then follows an elaborate rebuilding of the vehicle. The entire manual production process takes around 30 weeks, involving teams of authors, hundreds of photographers, and Haynes’ own expert technical personnel.

DIY Approach: Haynes strives to ensure their products are useful to anyone. Their objective is to enable all DIYers, and even beginners, to understand and effectively follow the manuals.

Mixed Content Types: The instructions mix text, images, and illustrations which complement and support each other in to effectively delivering the intended information.

Chapters & Sections: The manuals are divided into chapters which are further divided into sections. A contents table is provided to help users navigate to the desired section.

Numbering: Steps are numbered to create structure and allow users to move back and forth between them.

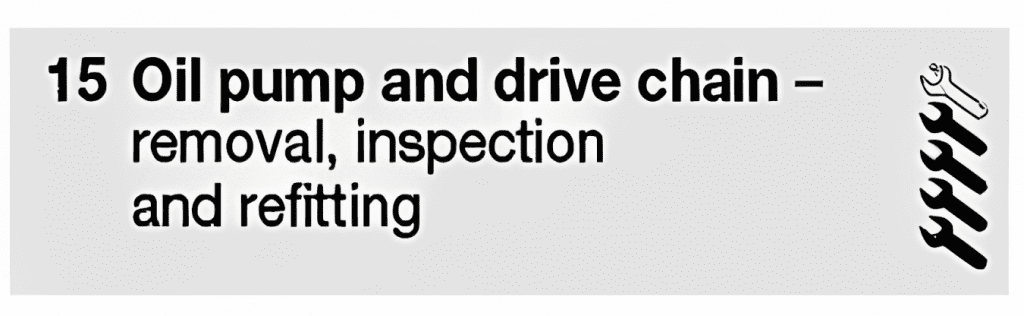

Difficulty Levels: Haynes use a Spanner Grading System to give users an indication of the level of difficulty associated with specific tasks:

1 Spanner: Easy, suitable for novice with little experience.

2 Spanners: Fairly easy, suitable for beginner with some experience.

3 Spanners: Fairly difficult, suitable for competent DIY mechanics.

4 Spanners: Difficult, suitable for experienced DIY mechanics.

5 Spanners: Very difficult, suitable for expert DIY or professional.

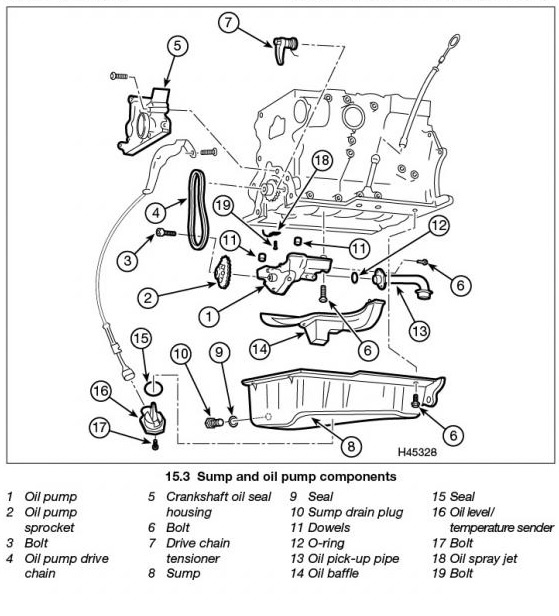

Piece Callouts: To assist users in understanding the names and functions of each piece, callouts are employed and highlight the components within various parts.

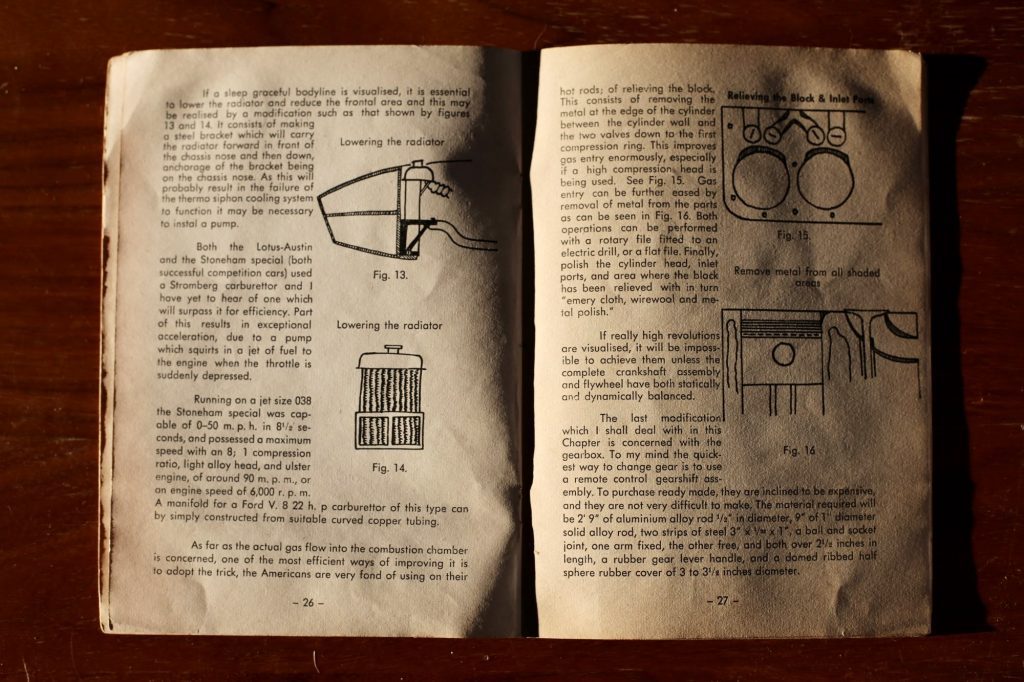

Evolution

The first Haynes manual was in many ways similar to the manuals we are familiar with today. More text-dense, it had illustrations to show procedures and describe the different parts. Although, it is evident that the manuals have evolved over time in response to general technical advancements. In the past, the illustrations were hand-drawn, and the use of photos was limited, which restricted the level of detail in the instructions. Today, they are able to incorporate more advanced techniques and visuals.

The first online Haynes Manual was published in 2011 and 9 years later, Haynes announced they would no longer produce any manuals in the traditional printed format. Instead, they decided to focus exclusively on producing them for digital use.

In 2021, Haynes launched Haynes AutoFix, an advanced online repair tool for motoring DIY tasks. A tool including technical drawings, DIY tutorials, instructional videos, an interactive fault finder, and much more – features not possible to provide with printed manuals. Andrew Golby, the Global Digital Director at Haynes, said “The way that people use automotive repair information has significantly changed since Haynes was first founded in the 1960s… In response, we’ve tapped into Haynes’ extensive, market-leading data to create an advanced repair tool that everybody can use.”.

Future

With the increased complexity of cars, the traditional concept of “DIY repair” has become significantly harder to perform without expert knowledge or specific equipment. When people buy cars, the ability to repair them is not what first comes to mind. Fuel efficiency, safety and price are factors more decisive. In response to customers’ needs and priorities, car manufacturers focus on those rather than making cars that are easy to work on.

However, there will always be a need for guidance on repairing cars, regardless of the complexity of the task. If Haynes remain committed to evolve and adapt in order to meet the constantly evolving automotive industry, they can maintain their position as the foremost provider of automotive repair guidance.